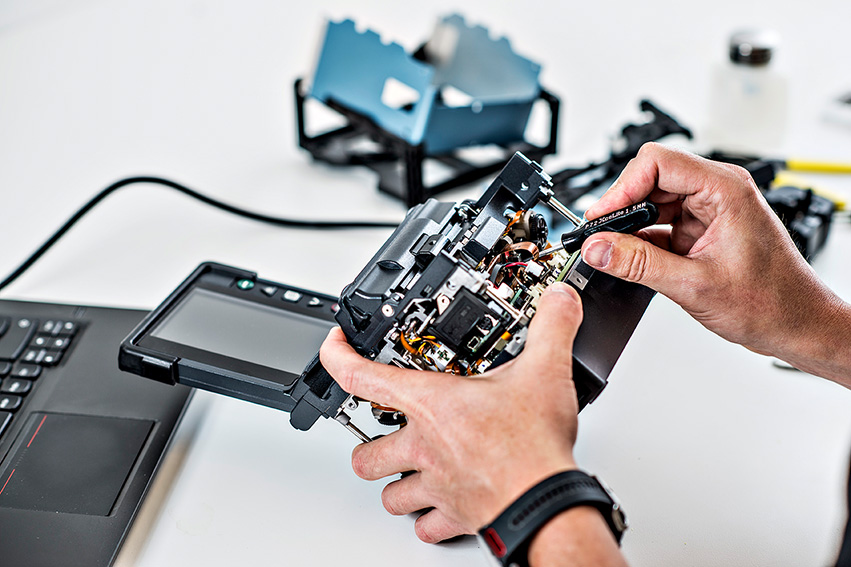

At BBT Fiberoptic, technical development and production are key priorities. Our development and production department works purposefully to transform customer-specific challenges into functional solutions. We utilize both our own developed product lines and tailor-made designs – including 3D-developed components – to meet demands for function, quality, and compatibility.

Our production and development department is located in Sunds near Herning – just minutes from the highway. Here, we have 1,000 m² of warehouse space and 800 m² of modern production facilities.

The team consists of dedicated employees focused on quality and customized solutions. We work diligently to understand your needs and turn them into functional, reliable products.

We are always ready to assist you with a solution to your specific challenge, so don’t hesitate to reach out to our department for a non-binding conversation – we might already have the solution you’re looking for.

Production – with a Focus on Quality, Flexibility, and Precision

As with the rest of BBT, quality, flexibility, and service are integral parts of the production department’s DNA.

In our production facility, we offer customized high-quality cable production. We manufacture, among other things, drop cables, patch cables, and special solutions based on specific requirements for length, connector types, and fiber standards.

We are equipped with professional measurement equipment for verifying polishing quality, insertion loss, and connector geometry, ensuring documented performance and consistent quality.

We also deliver high-precision mechanical components – either as in-house developed solutions or in close collaboration with the customer.

3D printing – Tailored Plastic Solutions

In our development department, we design and produce customer-specific components with high precision through 3D printing. We always aim to create long-lasting solutions. That’s why we work closely with our customers to develop solutions that meet both functional and technical requirements.

For example, we have developed our own custom-designed cable grommets for MICOS MDB fiber boxes based on specific customer requests.

Leading this effort is our Technical Designer, who brings a strong background in both construction and 3D printing technology, ensuring high expertise and a short path from idea to finished product.

Contacts:

Søren Adsersen – Department Manager

Phone: +45 4060 7716

Email: sa@bbtfiberoptic.dk

Anders Wolff – Technical Designer

Phone: +45 2117 8332

Mail: aw@bbtfiberoptic.dk